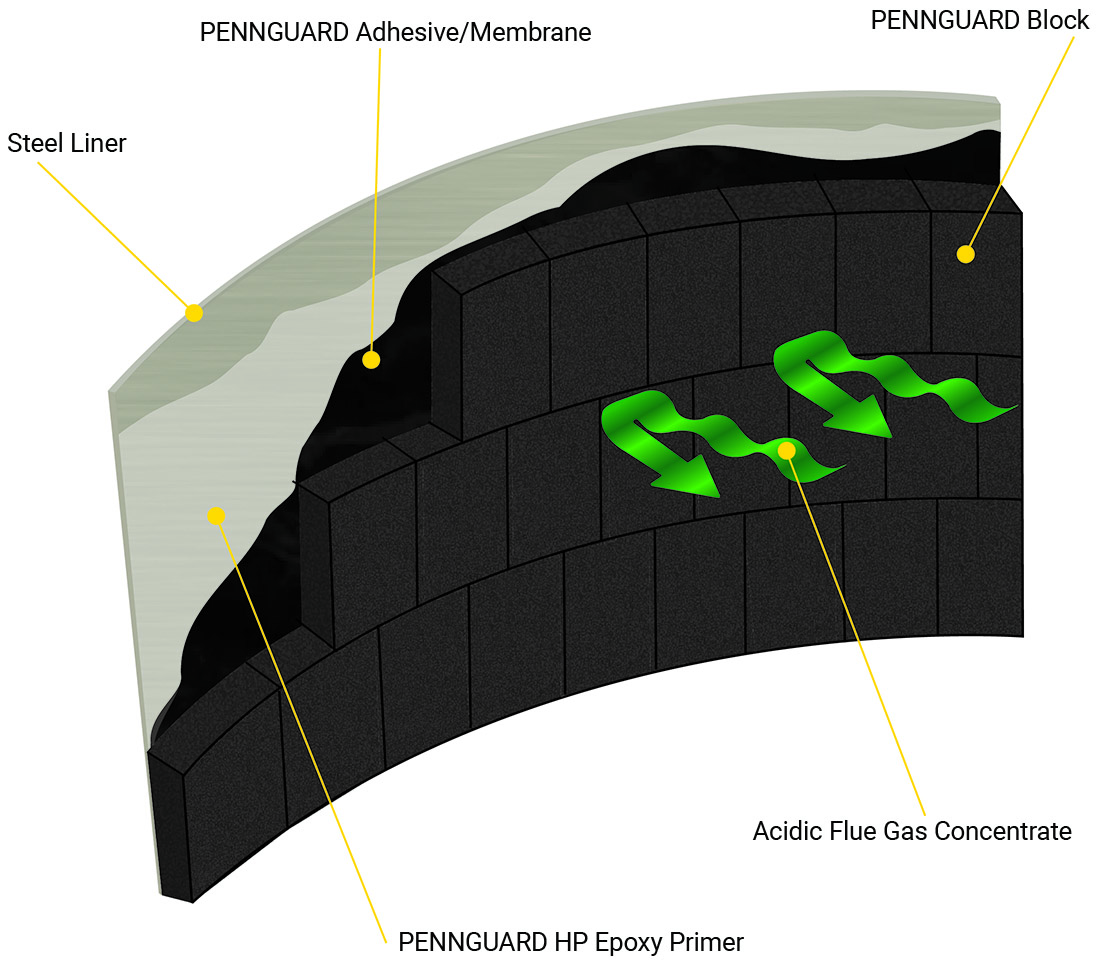

The unique combination of a rigid, closed-cell foamed glass block and flexible, elastomeric adhesive produces a protective barrier with performance that truly exceeds the sum of its parts.

- Chemical resistant

- Thermal shock resistant

- Heat resistant

- Fire resistant

- Lightweight

The unique combination of a rigid, closed-cell foamed glass block and flexible, elastomeric adhesive produces a protective barrier with performance that truly exceeds the sum of its parts.

- Chemical resistant

- Thermal shock resistant

- Heat resistant

- Fire resistant

- Lightweight

Ask if PENNGUARD™ is right for your plant.

Click to Contact UsSolutions

How can PENNGUARD help you?

New Construction

Retrofit

Ducts

Wet Stacks

Reheat/Bypass

Spitting

Seismic Zones

Leaks

Fire Protection

Interested in PENNGUARD?

Get in touch with us today and let our team show you how we can improve and safeguard your chimneys

What's your Substrate?

With the right surface preparation and primer, Pennguard Block Lining System adheres to a variety of substrates, both new and old, including steel, alloy, concrete, gunite, ceramic brick, fiberglass reinforced plastic (FRP), and resinous polymer coatings. Consider the benefits of Pennguard to protect your existing or new flues.

Mouse over or tap a material for more information.

Fiberglass

Brick

Steel

Concrete

Proven Performance

With a track record spanning more than 40 years and 30 countries, PENNGUARD Block Lining System has earned its global reputation for reliability and versatility. See which power plants picked PENNGUARD. See which power plants picked PENNGUARD.

Featured Project

Lignite fired power station renews its flue gas desulfurization system and converts its existing chimney to a PENNGUARD™ lined wet stack.

- Lignite fueled power station, 330MW and 650MW

- Wet limestone FGD

- 135m high reinforced concrete chimney with sectional brick flue

- PENNGUARD™ lining applied directly to the internal surface of the brick flue