PENNGUARD™ Design

The unique combination of a rigid, closed-cell foamed glass block and flexible, elastomeric adhesive produces a protective barrier with performance that truly exceeds the sum of its parts.

Features

- Chemical Resistant: Low temperature wet flue gas to high temperature untreated gas, even with high SO3 content

- Thermal Shock Resistant: Tolerates cycling and bypass operating conditions

- Heat Resistant: Handles gas temperatures up to 392°F (200°C)

- Fire Resistant: FM Approved for steel flues

- Lightweight: Adhesively bonded lining weighs only 12-15 kg/m2

System Components

Steel Primer

PENNGUARD™ HP Epoxy Primer Product Data Sheet SDS Part A Resin SDS Part B Hardener SDS Part A Resin SDS Part B Hardener

Concrete/Brick Primer

PENNTROWEL™ Epoxy Primer Product Data Sheet SDS Part A Resin SDS Part A Resin SDS Part B Hardener SDS Part B Hardener SDS Part A Resin SDS Part B Hardener

Adhesive

PENNGUARD™ Adhesive/Membrane Product Data Sheet SDS Part A Resin SDS Part A Resin SDS Part A Resin SDS Part A Resin SDS Part B Hardener SDS Part B Hardener SDS Part B Hardener SDS Part A Resin

Substrates

With the right surface preparation and primer, Pennguard Block Lining System adheres to a variety of substrates, both new and old, including steel, alloy, concrete, gunite, ceramic brick, fiberglass reinforced plastic (FRP), and resinous polymer coatings. Consider the benefits of Pennguard to protect your existing or new flues.

Mouse over or tap a material for more information.

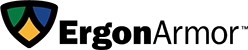

Steel

PENNGUARD Adhesive/Membrane, a urethane-modified asphalt elastomeric adhesive, gives PENNGUARD Block Lining System its flexibility and liquid tightness. Behind the insulating PENNGUARD Block, the uniform and continuous 1/8-inch (3mm) layer of PENNGUARD Adhesive/Membrane remains pliable and intact to protect the substrate.

PENNGUARD Block, manufactured of foamed glass, has a closed-cell structure to insulate the PENNGUARD Adhesive/Membrane and prevent acidic gas and condensate from breaching the lining. Standard size is 6 x 9-inch (152 x 228 mm) x 1-inch (25 mm), 1.5-inch (38 mm) or 2-inch (50 mm) thickness to suit the anticipated service conditions.

PENNGUARD HP Epoxy Primer, a fast-drying epoxy primer, provides protects freshly grit-blasted steel from re-rusting and promotes adhesion to the PENNGUARD Adhesive/Membrane.

Acidic Flue Gas Condensate, closed cell borosilicate block does not allow any penetration of acid gas or acid condensates even under positive pressure conditions.

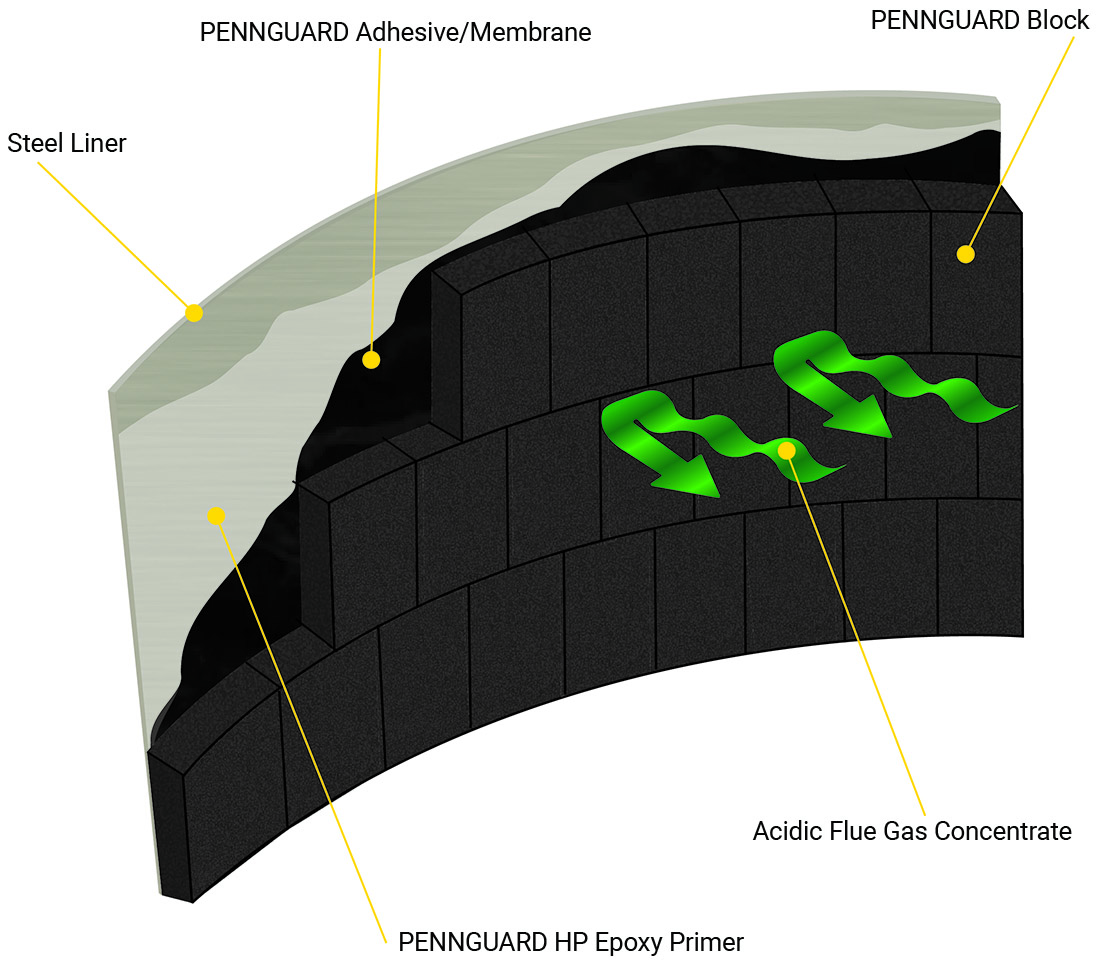

Concrete

PENNGUARD Adhesive/Membrane, a urethane-modified asphalt elastomeric adhesive, gives PENNGUARD Block Lining System its flexibility and liquid tightness. Behind the insulating PENNGUARD Block, the uniform and continuous 1/8-inch (3mm) layer of PENNGUARD Adhesive/Membrane remains pliable and intact to protect the substrate.

PENNGUARD Block, manufactured of foamed glass, has a closed-cell structure to insulate the PENNGUARD Adhesive/Membrane and prevent acidic gas and condensate from breaching the lining. Standard size is 6 x 9-inch (152 x 228 mm) x 1-inch (25 mm), 1.5-inch (38 mm) or 2-inch (50 mm) thickness to suit the anticipated service conditions.

PENNGUARD HP Epoxy Primer, a fast-drying epoxy primer, provides protects freshly grit-blasted steel from re-rusting and promotes adhesion to the PENNGUARD Adhesive/Membrane.

Acidic Flue Gas Condensate, closed cell borosilicate block does not allow any penetration of acid gas or acid condensates even under positive pressure conditions.

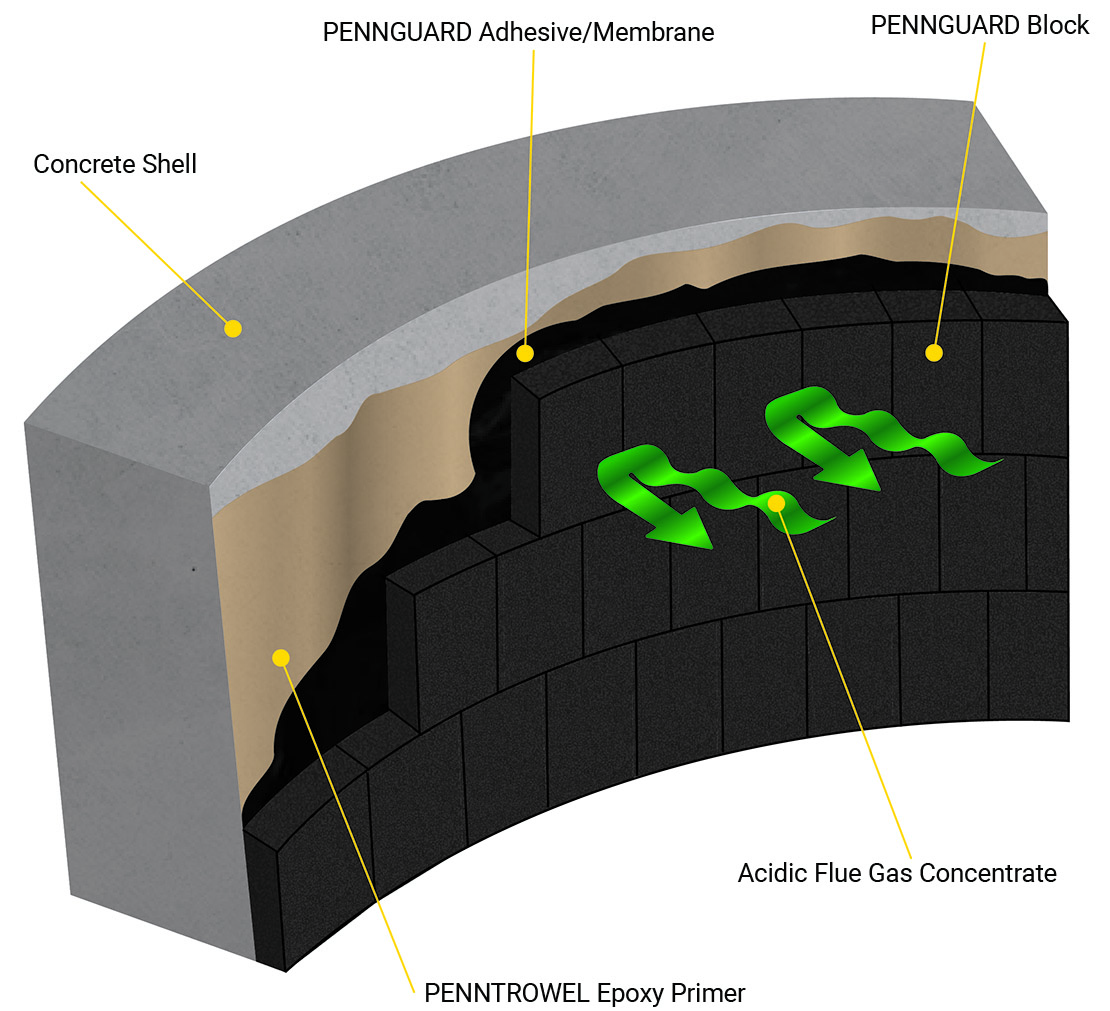

Brick

PENNGUARD Adhesive/Membrane, a urethane-modified asphalt elastomeric adhesive, gives PENNGUARD Block Lining System its flexibility and liquid tightness. Behind the insulating PENNGUARD Block, the uniform and continuous 1/8-inch (3mm) layer of PENNGUARD Adhesive/Membrane remains pliable and intact to protect the substrate.

PENNGUARD Block, manufactured of foamed glass, has a closed-cell structure to insulate the PENNGUARD Adhesive/Membrane and prevent acidic gas and condensate from breaching the lining. Standard size is 6 x 9-inch (152 x 228 mm) x 1-inch (25 mm), 1.5-inch (38 mm) or 2-inch (50 mm) thickness to suit the anticipated service conditions.

PENNGUARD HP Epoxy Primer, a fast-drying epoxy primer, provides protects freshly grit-blasted steel from re-rusting and promotes adhesion to the PENNGUARD Adhesive/Membrane.

Acidic Flue Gas Condensate, closed cell borosilicate block does not allow any penetration of acid gas or acid condensates even under positive pressure conditions.

Interested in PENNGUARD?

Get in touch with us today and let our team show you how we can improve and safeguard your chimneys